The rise of advanced manufacturing and how to leverage technology to excel in it

There is plenty to admire in the longevity and vitality of the manufacturing industry as one of the most enduring and vibrant sectors in propelling economic growth. One of the key drivers behind the success of this industry is its continuous evolution, growing in parallel with the quantum leap in technology.

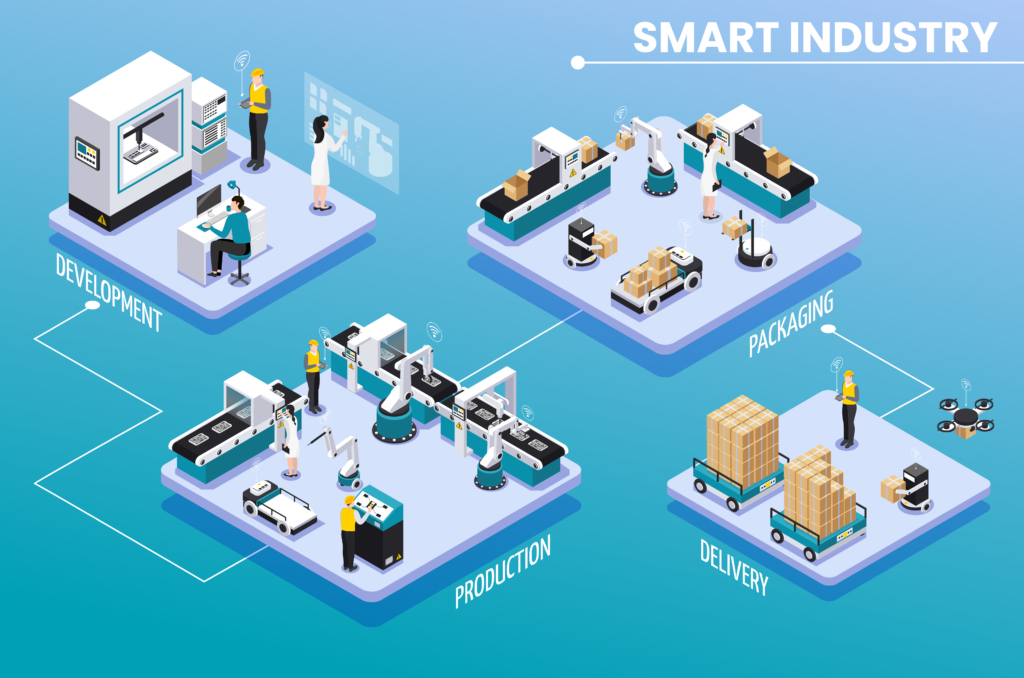

The nascent manufacturing industry was characterised by workers slogging away to meet manufacturing demand, which in turn was driven by consumer demand for certain products. However, the turn of the 21st century ushered in a period of significant advancement which saw manufacturing shed its image as a heavy-duty, cheap-labour, product-churning juggernaut, to become an industry driven by cutting-edge technology, providing high-income jobs, catering to an endless stream of new demand brought about by the various by-products of the Fourth Industrial Revolution (IR4.0), such as the Internet of Things (IoT), automation, and artificial intelligence (AI).

In Singapore, the manufacturing industry makes up between 20% and 25% of the island nation’s GDP. The Singapore government has signalled its intention to get fully onboard the advanced manufacturing sector by setting a target to grow this industry by 50% over the next 10 years.

“Beyond the 50% increase in value, we want to see a greater proportion of our manufacturing going into advanced manufacturing, where the competition is not based on cost but based on the intellectual property that we can generate, the quality of the products and the precision that we can provide for the sector,” said Singapore’s Trade and Industry Minister Chan Chun Sing, earlier this year.

The Hitachi Solutions’ research titled 11 Trends That Will Dominate Manufacturing in 2021 predicts IoT to become one of the dominant technologies in the manufacturing sector, driven by its ability to enable factories to make informed decisions using real-time data. A third of production mechanisms incorporate smart devices, with 34% of manufacturers indicating their intentions to incorporate IoT into their processes and 32% of companies planning to embed it into their products.

The production of semiconductor devices is expected to further fuel the growth of the manufacturing industry. This is largely driven by digital-age necessities such as the prevalence of semiconductors in everything we use in our daily lives such as mobile phones and computers. In addition to this, manufacturers are also increasingly becoming cognizant of their responsibilities towards the environment, as exemplified by the increased importance placed on environmental, social, and governance (ESG) practices.

As manufacturers transition from a labour-intensive environment to a high-skilled working environment, there is plenty that cloud solutions have to offer to optimise their workforce and operate efficiently. Manufacturers are increasingly finding themselves operating in a highly competitive environment where early adopters of technology are reaping the full benefits of the digital revolution. The emphasis on ESG also requires manufacturers to make full use of technology in order to operate in an environmentally sustainable manner.

Below we look at how cloud technology in its present form can help manufacturers compete on an international level and carve out a niche for themselves.

Total Visibility and Single Source of Truth

The Deloitte 2022 Manufacturing Industry Outlook underlines visibility as an imperative capability for manufacturers in the post-Covid-19 world. As illustrated by the recent supply chain bottlenecks, having best in class technologies such as a cloud ERP system can help businesses deal with the uncertainties unleashed by the Covid-19 pandemic. Cloud systems offer manufacturers unprecedented visibility over their business and act as a single source of truth.

Easy Low-Code/No-Code Integrations

Manufacturing businesses often deal with various stakeholders such as distributors, vendors, and suppliers who use different business solutions. Having a dedicated IT team to deal with each and every system that a factory encounters can be a tedious, costly and heavily time-consuming process. Systems integration solutions provide manufacturing businesses with easy low-code/no-code integrations that in turn enable workflow automation.

CRM

Cloud solutions offer manufacturers a real-time, 360-degree view of their customers. They also offer solutions that provide manufacturing businesses with a seamless flow of information cutting across the entire customer lifecycle, from lead through opportunity, sales order, fulfilment, renewal, upsell, cross-sell and support.

Product Data Management

Product-based cloud solutions come equipped with robust functionalities to help manufacturers create and manage master data critical in the running of manufacturing, entailing items, customers, partners, and vendors.

Order Management

In a fast-paced, digital business environment, manufacturers need solutions that can help them respond swiftly to consumer demands. Solutions such as intelligent order management systems help businesses automate order processing, allocation, orchestration, and execution processes that are critical when operating in a global business environment.

Planning and Scheduling

Planning and scheduling is now a pivotal component for all manufacturing businesses. Planning and scheduling help companies to correctly estimate the allocation of resources, operations and processes required in order to create goods and services. Cloud manufacturing software can help manufacturers perform real-time scheduling, which helps their companies operate efficiently.

Procurement

For product-based manufacturing businesses, it is of vital importance that key components in the production process are in adequate supply. The recent pandemic only further highlighted the importance of manufacturing companies to equip themselves with the best that cloud solutions can offer. These solutions ensure that manufacturers are equipped with the right materials, at the right time and at the right place.

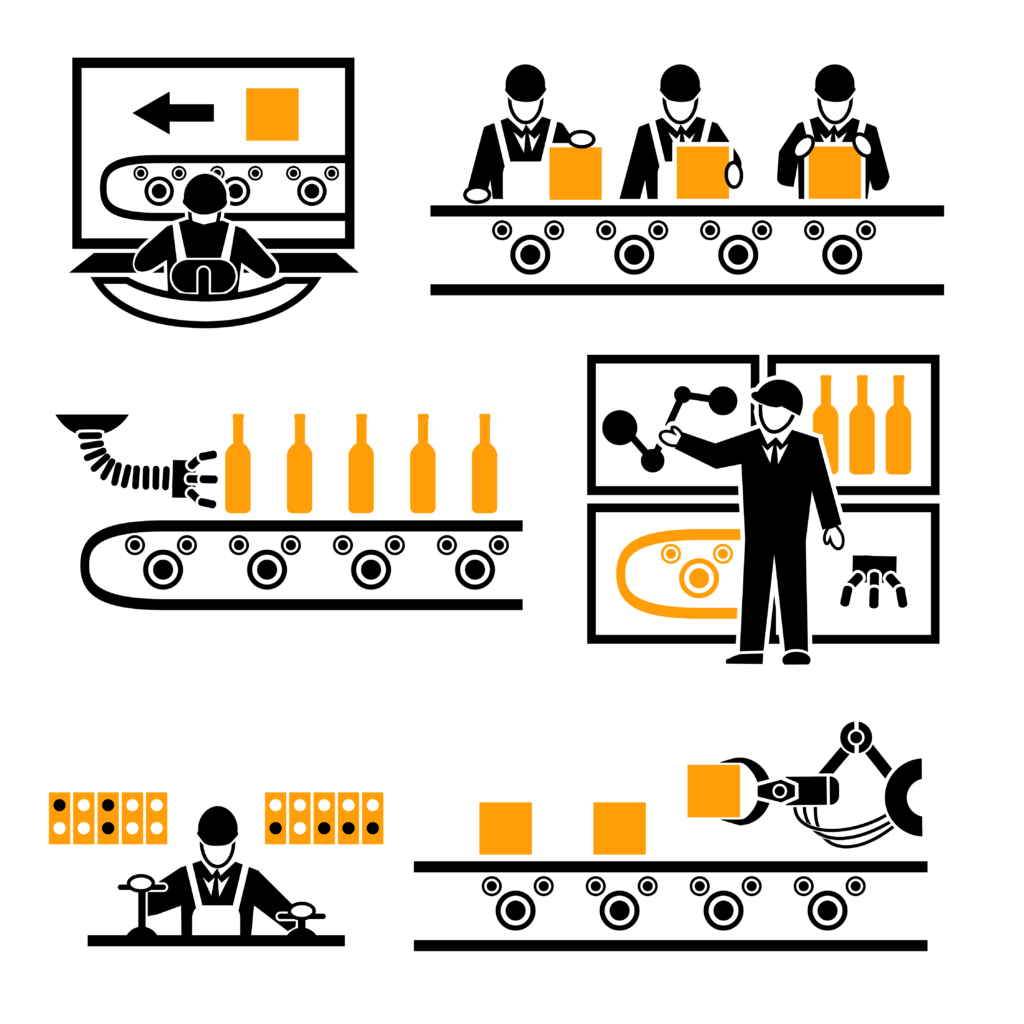

Production Control

With manufacturers’ wide array of systems, businesses can create, release, update, and monitor work orders throughout their production process. Best in class solutions for manufacturing give businesses the flexibility to manage their production process exactly the way they want and ensure the production process fits their facilities and data requirements.

Supply Chain Management

Hardly a day goes by without news of supply chain bottlenecks causing mayhem in different parts of the world and creating massive inconveniences for customers. In an increasingly uncertain world where Covid-19 is an endemic disease, businesses do not have a choice but to deploy best in class technology that will help them navigate through choppy waters. Cloud technology for the manufacturing industry ensures that the concept of where your product is manufactured and who it is manufactured by becomes irrelevant. These solutions give businesses a global view of all their inventory, regardless of where it is or who it is being consumed by.

Shop Floor Control

Shop floor control (SFC) is a set of software that helps manufacturing companies track, schedule, and report on the progress of work in a manufacturing plant. The selection of cloud solutions available in the market will help manufacturing businesses easily gather real-time information from the manufacturing process through user-configurable tablet applications that allow users to optimise the system on the fly.

Quality Management

Delivering products of the highest quality to customers is often the purpose of any business, and this requires the combination of company-wide commitment to the cause and the usage of top-notch technologies. Quality management systems come with features that help businesses define and maintain inspection plans and deliver high-quality products with minimal overhead.

Oracle NetSuite

Oracle NetSuite is the world’s leading cloud enterprise resource planning (ERP) system, having been deployed in 40,000 companies and subsidiaries across 160 countries.

Workato

Find out how you can introduce low-code/no-code integrations to connect your system, and enable workflow automation